PROVIDE FIRST TIME SEWAGE TO VILLAGES IN NORFOLK, UK

PROVIDE FIRST TIME SEWAGE TO VILLAGES IN NORFOLK, UK

Country: England

Length of Pipe: 1.2km

No. of Vacuum Stations: 1

No. of Interface Valves: 15

Volume of Flow: 5 litres/sec

Specialist Feature: Iseki Wireless Radio Valve Monitoring Caisson building structure used for construction of deep Vacuum Station basement.

Our client undertook works to provide first time sewerage to 131 properties in the villages of Swafield and Bradfield, Norfolk. The need was identified as the soil conditions were unsuitable for the septic tank drainage systems that were originally in place. The separated wastewater from the tanks was unable to effectively pass through the particles of the sub soils and into drainage fields. This was causing serious adverse effects on the environment and the health of residents.

The wider scope of works included the construction of a sewerage network consisting of approximately 4km of pipes connecting to customers’ properties, 4km of pumped main with three package pumping stations and 1.2km of vacuum main with one vacuum pumping station.

Within the village of Bradfield, the only piece of land available for a pumping station was on the edge of the village on higher ground. Vacuum sewers can be laid in flat terrain, and parts may even flow uphill (within limits), making this project ideal for vacuum sewerage technology.

The water table was found to be exceptionally high in Bradfield and in order to keep the vacuum sewer network within hydraulic limitations, it was necessary to install a deep vacuum vessel and therefore construct a Vacuum Station basement 4m below ground level.

Iseki worked alongside the Client and the Contractor to develop a suitable station design for the conditions with a cylindrical caisson design being the preferred choice.

A caisson is a structure commonly used in civil engineering projects where work is being carried out in areas submerged in water. A Concrete ring is created by bolting together precast sections. The ring is then sunk into place and the soil inside the structure excavated. Caissons differ from cofferdams in that cofferdams are removed after completion of the work, whereas caissons are built to remain in place as a part of the completed structure.

Vacuum Pipework

Vacuum sewers in SDR 17 HDPE sizes from Ø90mm – Ø125mm with electro-fusion joints.

Vacuum Station Equipment

One station operating with three dry claw vacuum pumps each rated at 200m³/hr (Busch) together with two dry well screw centrifugal discharge pumps (Hidrostal).

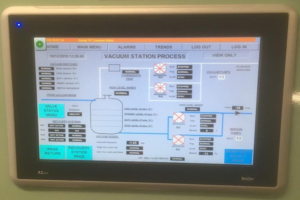

Vacuum collection vessel 4m³ fully tested to Lloyds certification. Motor control centre fully automatic with a HMI/PLC arrangement. All pumps start in rotation and all conditions are monitored with a data logging system.

Iseki wireless radio valve monitoring system which continuously monitors for the occurrence of the following events:

- An excessive number of interface valve operations in a predetermined time period

- An interface valve remaining open for an excessive time period

- High level of sewage inside the valve chamber

Summary

Another successful collaborative project between the UK’s largest operator of vacuum sewage systems, a framework Contractor, and the UK’s leading vacuum sewage technology specialists, Iseki.